In the dynamic world of manufacturing and quality control, precision is paramount. The ability to produce components and products that meet exact specifications is not just a competitive advantage but a necessity. This is where accredited calibration services play an indispensable role, ensuring that measurement instruments provide accurate readings, thereby maintaining the integrity of manufacturing processes and product quality.

Calibration involves comparing the measurements from an instrument against a recognized standard to detect any deviations or errors. Accredited calibration services are those that have been certified by authoritative bodies to perform these tasks according to international standards. Accreditation serves as a mark of competence and reliability, assuring manufacturers that their tools will be calibrated accurately.

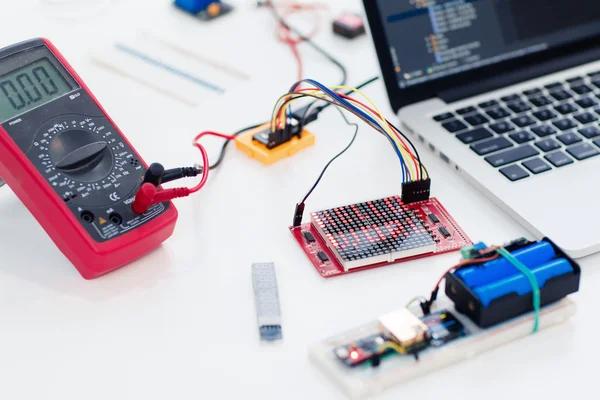

find the source here significance of using accredited calibration services cannot be overstated in industries where precision matters most, such as aerospace, automotive, pharmaceuticals, and electronics. In these sectors, even minute discrepancies can lead to significant issues ranging from product recalls to safety hazards. By ensuring equipment accuracy through regular calibration checks performed by accredited providers, companies can mitigate risks associated with defective products or non-compliance with industry regulations.

Moreover, utilizing accredited services helps maintain consistency across production lines. When all instruments are calibrated using standardized procedures verified by accreditation bodies like ISO/IEC 17025:2017 for laboratory testing and calibration competencies, there’s uniformity in measurements regardless of geographical location or time frame. This consistency not only enhances internal operations but also strengthens trust among clients who rely on precise specifications for their own processes.

Accredited calibration also plays a crucial role in fostering innovation within the manufacturing sector. As technology evolves rapidly with advancements like automation and smart factories becoming more prevalent, having reliable measurement systems ensures new technologies function optimally without introducing errors into production cycles. Manufacturers investing in cutting-edge technologies require assurance that their innovations will perform as expected under real-world conditions; this confidence stems largely from knowing their equipment has been precisely calibrated by trusted professionals.

Furthermore, partnering with accredited service providers often brings additional benefits such as expert consultation on best practices for maintaining equipment accuracy over time and tailored solutions specific to unique operational needs—adding value beyond basic compliance requirements.

In conclusion, accredited calibration services form the backbone of effective manufacturing and quality control strategies today. They ensure precision in production processes while safeguarding against costly errors linked with inaccurate measurements—a critical factor driving success amid increasing market competition globally.